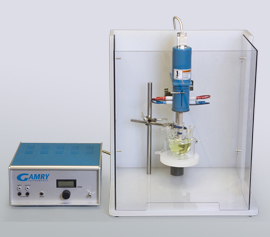

POTENTIOSTAT / GALVANOSTAT

The Interface 1010 is a value oriented, general purpose potentiostat for almost all applications except for high current electrochemistry.

The "T(eaching)" version of the Interface 1010 can be purchased flexibly at a low entry level budget for almost all applications in electrochemical research and -industry. Later, if requirements increase, existing electronic components with higher specifications can be activated by means of a paid upgrade.

The latest development in the Reference 600 series - the Reference 620 - features 20-bit analog/digital conversion, gaining about a decade of additional sensitivity. This makes the system the first choice for demanding applications, e.g. in basic research.

The Reference 620 offers eleven current ranges between 60 pA - 600 mA at a maximum of ± 12 V at the working electrode. Two additional gain stages (10x / 100x) extend to an even broader current range of 13 decades, allowing electrochemical impedance spectroscopy (EIS) on very high ohmic surrogates between 5 MHz and 10 µHz with current resolutions down to 20 aA per bit using state-of-the-art microelectronics and oversampling. Careful selection of electronic components and design result in...

LAB PRESSURE REACTORS – 0.25-5.0 LITRES

Safety and flexibility for a wide range of pressure applications in steel and glass vessels

Flexible, modular pressure reactor system for laboratory/technical laboratory applications for volumes from 0.25 to 5 litres and pressures between 6 and 200 bar. The robust stainless-steel frame with polycarbonate door allows safe pressure reactions with glass vessels. An optional vessel lift with safety fast action closure provides easy and safe handling.

Flexible and robust- even under high pressure

The versoclave is an extremely flexible pressure reactor system for steel reactors between 0.5 and 5 liters in stainless steel, Hastelloy and special alloys. The system is equipped with 60 bar reactors with/without sight glass and can be upgraded up to 200 or 350 bar as a standard option. The open frame offers enough space for process-technical attachments.

Compact, modular, excellent price/performance ratio, ss/metal pressure reactor system with 0.5 / 1 liter volumina

Modular pressure reactor system for steel and glass reactors of 0.5 - 1 litre. For safe performance of pressure reactions in glass reactors, the Uniclave has a shatterproof housing with polycarbonate sliding door.

SMALL PRESSURE REACTOR – 10-300ML

small volumina – strong magnetic drive

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 100-300ml. The compact system can be placed in every fume cupboard. A safety fast action closure allows quick and easy opening and removal of the reactor without tools.

Safety and flexibility with small scale glass and steel reactors

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 50-300ml. The robust stainless-steel frame with polycarbonate door also allows safe pressure reactions with glass pressure vessels. The safety fast action closure allows a quick vessel change or cleaning - without tools.

PRESSURE REACTORS FOR KILO LAB & PRODUCTION

Safe pressure reactions up to 20 litres in laboratory/kilo lab or in small scale production

The Buchi Kiloclave is ideal for up-scaling processes or small scale production, reactors between 0.5 and 20 liters can be used on the same cover plate. Due to its robust frame with hydraulic reactor lift and tilt function, it is particularly suitable for larger reactors and process-technical attachments.

Safe pressure application on a pilot scale up to 500 litres

Büchi builds pilot plants for process engineering pressure and vacuum applications mainly for the chemical and pharmaceutical industry. Depending on the process and process media, the plants are designed in different materials and manufactured for pressures up to 200 bar and volumes up to 300 liters. Typical applications are the pilot plant for process optimization or process development as well as production plants for the manufacture of small quantities.

HIGH PRESSURE REACTORS

Safe and comfortable working under high pressure

The midiclave is a flexible high-pressure reactor for a pressure range of up to 200 bar. It can be operated with various interchangeable metal pressure vessels up to 1 litre volume with or without sight glasses. Thanks to the built-in safety precautions and the fast action closure, pressure reactions can be carried out safely and comfortably.

Reach new dimensions in terms of pressure and temperature

The Buchi novoclave is designed for extreme conditions of up to 500 bar and up to 500°C. For supercritical reactions, hydrogenation, material and catalyst tests, reactors between 100 and 600 ml can be used. The reactors are tempered by electrical heating with PID controller and built-in automated tap water cooling, magnetic valve controlled.