CRYOGENIC GRINDERS

The Cole-Parmer CG-400 Freezer/Mill® Cryogenic Grinder (formerly SPEX 6785 Freezer/Mill) - the first choice for grinding sample quantities from 0.1 to 100g for temperature sensitive samples or samples that cannot be ground at room temperature.

The basic model in the Cole-Parmer Freezer/Mill range requires manual filling with liquid nitrogen. Continuous cooling of the sample container in liquid nitrogen, robust mechanics with only one moving part and intuitive touch screen operation ensure maximum efficiency and durability.

The Cole-Parmer CG-450 Freezer/Mill® cryogenic grinder (formerly SPEX 6875 Freezer/Mill) – including the Auto-Fill – function. The first choice for grinding sample quantities between 0.1 and 100g in the case of temperature-sensitive samples or samples that are impossible to grind at room temperature.

The sister model of the CG-400 is filled with liquid nitrogen automatically. The permanent cooling of the sample container in liquid nitrogen, the robust mechanics with only one moving part and the intuitive touchscreen operation ensure maximum efficiency and durability.

The CG-500 Freezer/Mill® is a high-throughput, dual chamber, cryogenic grinder. It accommodates samples in the 0.1 to 200g range (100g per grinding chamber). Each grinding chamber can hold one large grinding vial or four standard grinding vials. Sample vial maintains cryogenic temperatures due to continuous immersion in liquid nitrogen.

When performance matters: The top model from the Freezer/Mill series offers two grinding chambers, two pre-cooling chambers and the choice of manual or automatic filling with liquid nitrogen. The permanent cooling, the robust mechanics and the intuitive touchscreen operation ensure maximum efficiency and durability.

PLANETARY MIXERS

The latest development in the Reference 600 series - the Reference 620 - features 20-bit analog/digital conversion, gaining about a decade of additional sensitivity. This makes the system the first choice for demanding applications, e.g. in basic research.

The Reference 620 offers eleven current ranges between 60 pA - 600 mA at a maximum of ± 12 V at the working electrode. Two additional gain stages (10x / 100x) extend to an even broader current range of 13 decades, allowing electrochemical impedance spectroscopy (EIS) on very high ohmic surrogates between 5 MHz and 10 µHz with current resolutions down to 20 aA per bit using state-of-the-art microelectronics and oversampling. Careful selection of electronic components and design result in...

The high-end potentiostat for all demanding applications in electrochemistry from very low to high currents.

The Reference 3000 offers eleven current ranges between 300 pA - 3000 mA at a maximum of either ±3A@±15V or ±1.5A@±32V at the working electrode. Two additional gain stages (10x / 100x) extend to an even broader current range of 13 decades, allowing electrochemical impedance spectroscopy (EIS) on very high ohmic surrogates between 1 MHz and 10 µHz with current resolutions down to 100 aA per bit using state-of-the-art microelectronics and oversampling. Careful selection of electronic components and design result...

The well-known high-end Reference 3000AE Potentiostat/Galvanostat/ZRA with eight additional auxiliary electrometers (AE).

With the eight additional channels of the Auxiliary Electrometer (AE) add-on option of the Reference 3000 Potentiostat / Galvanostat / ZRA, potential differences of either eight individual half cells of a stack or up to eight peripherical signal transducers can be measured. Each of the eight available electrometers (± 5 V vs. counter electrode potential) can clarify the impedance of a half cell in an electrochemical impedance spectroscopy measurement performed over the entire stack or to simply measure eight additional...

The Reference 3000 (AE) Potentiostat/Galvanostat/ZRA high performance and multi-purpose basic unit can be combined with the Reference 30k Booster and is ideal for evaluating new highest-level technologies for batteries, fuel cells, supercapacitors and high turnover electrochemical synthesis.

The Reference 3000 is already a high-performance system, but with the addition of the Reference 30k booster, it can serve even more demanding applications. You can therefore make a valuable contribution at the highest level in basic research, electrochemical synthesis, and electrochemical energy storage. The Reference 3000 basic instrument can either be equipped later with 8 additional auxiliary electrometers (AE; Auxilliary Electrometer) by means of a hardware upgrade, or you can opt for the Reference 3000AE.

Interface for loads and power supplies for EIS characterization of batteries and fuel cells available in three versions (10 V, 100 V and 1000 V)

Alternatives to fossil fuel energy sources are becoming more and more prevalent, and fuel cells and batteries are playing an important role in energy storage and conversion of these alternatives. However, their future success depends on continuously improving efficiency and performance, which you can now do much better with Gamry's LPI1010 Load- / Power-Supply Interface.

HIGH-POWER POTENTIOSTATS

The PTC series is used for measurements with high current requirements, e.g. for the characterisation of electrolysers or fuel cells

The 4-quadrant potentiostats/galvanostats of the PTC series are available with four power ranges up to max. ±100A@±5V. Impedance spectroscopy (EIS) is possible via two channels between 1 mHz and 100 kHz. This means that tasks in general electrochemical synthesis, from water splitting and alkaline CO2 conversion to fuel cells and other energy storage and conversion concepts, can also be successfully mastered on larger surfaces with higher material conversion and higher current requirements.

Modular configurable multi-channel (up to 1000 individual cells) impedance test stand for fuel cell and electrolysis cell stacks as well as Li-ion and redox flow battery packs

The MegaEIS multi-channel electrometer/impedance spectroscopy test stand enables the characterisation and optimisation of up to 1000 individual cells, e.g. of a fuel cell or electrolysis cell stack up to 1000 V / 2000 A within a power limit of 250 kW. For tasks in general electrochemical synthesis from water splitting and alkaline CO2 conversion to fuel cells and other energy storage and conversion concepts - also on an industrial scale.

POTENTIOSTAT - MULTI-CHANNEL SYSTEMS

The Interface 1010 Bipotentiostat System from Gamry is compact, flexible, and inexpensive for all kinds of electrochemical measurements using two channels.

Each channel of the Interface 1010 bipotentiostat with its eleven current ranges including 10x / 100x gain record currents from 100 pA to 1 A at ± 12 V working electrode potential. The Interface 1010 Bipotentiostat is shipped including a special cable for synchronization. Since the systems are floating from protective ground, synchronous operation without mutual interference is possible.

Multi-channel systems are ideal for any application where significance can be increased by higher experimental throughput.

With the multi-channel potentiostat from Gamry, a single system can be flexibly configured from many channels for research purposes with high significance. Flexibility means to operate each channel individually, in groups or all together. Each channel covers either a current range from 100 pA to 1 A (IFC1010) or from 500 nA to 5 A (IFC5000) and can maintain a maximum potential of either ± 12V (IFC1010) or ± 6V (IFC5000) at the working electrode.

LAB PRESSURE REACTORS – 0.25-5.0 LITRES

Safety and flexibility for a wide range of pressure applications in steel and glass vessels

Flexible, modular pressure reactor system for laboratory/technical laboratory applications for volumes from 0.25 to 5 litres and pressures between 6 and 200 bar. The robust stainless-steel frame with polycarbonate door allows safe pressure reactions with glass vessels. An optional vessel lift with safety fast action closure provides easy and safe handling.

Flexible and robust- even under high pressure

The versoclave is an extremely flexible pressure reactor system for steel reactors between 0.5 and 5 liters in stainless steel, Hastelloy and special alloys. The system is equipped with 60 bar reactors with/without sight glass and can be upgraded up to 200 or 350 bar as a standard option. The open frame offers enough space for process-technical attachments.

Compact, modular, excellent price/performance ratio, ss/metal pressure reactor system with 0.5 / 1 liter volumina

Modular pressure reactor system for steel and glass reactors of 0.5 - 1 litre. For safe performance of pressure reactions in glass reactors, the Uniclave has a shatterproof housing with polycarbonate sliding door.

SMALL PRESSURE REACTOR – 10-300ML

Modularity and safety for a wide range of pressure applications in steel and glass vessels

Flexible reactor system for different applications, optionally with steel or glass reactors from 100-300ml. Visual process control and monitoring of your reaction can be carried out in the glass reactors up to 10 bar. Use steel reactors, you can work up to 100 bar and optionally use PTFE Inliner.

small volumina – strong magnetic drive

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 100-300ml. The compact system can be placed in every fume cupboard. A safety fast action closure allows quick and easy opening and removal of the reactor without tools.

Safety and flexibility with small scale glass and steel reactors

Very flexible, modular pressure reactor system for a wide range of applications with small approaches in the range of 50-300ml. The robust stainless-steel frame with polycarbonate door also allows safe pressure reactions with glass pressure vessels. The safety fast action closure allows a quick vessel change or cleaning - without tools.

PRESSURE REACTORS FOR KILO LAB & PRODUCTION

Safe pressure reactions up to 20 litres in laboratory/kilo lab or in small scale production

The Buchi Kiloclave is ideal for up-scaling processes or small scale production, reactors between 0.5 and 20 liters can be used on the same cover plate. Due to its robust frame with hydraulic reactor lift and tilt function, it is particularly suitable for larger reactors and process-technical attachments.

Safe pressure application on a pilot scale up to 500 litres

Büchi builds pilot plants for process engineering pressure and vacuum applications mainly for the chemical and pharmaceutical industry. Depending on the process and process media, the plants are designed in different materials and manufactured for pressures up to 200 bar and volumes up to 300 liters. Typical applications are the pilot plant for process optimization or process development as well as production plants for the manufacture of small quantities.

HIGH PRESSURE REACTORS

Safe and comfortable working under high pressure

The midiclave is a flexible high-pressure reactor for a pressure range of up to 200 bar. It can be operated with various interchangeable metal pressure vessels up to 1 litre volume with or without sight glasses. Thanks to the built-in safety precautions and the fast action closure, pressure reactions can be carried out safely and comfortably.

Reach new dimensions in terms of pressure and temperature

The Buchi novoclave is designed for extreme conditions of up to 500 bar and up to 500°C. For supercritical reactions, hydrogenation, material and catalyst tests, reactors between 100 and 600 ml can be used. The reactors are tempered by electrical heating with PID controller and built-in automated tap water cooling, magnetic valve controlled.

GASDOSING-/HYDROGENATION SYSTEMS, PARALLEL REACTOR

BPC 2 - gas dosing unit for reliable and reproducible hydrogenation

The Buchi BPC 2, which consists of a gas regulator and control unit, is a fully integrated gas dosing system for the safe and reproducible performance of hydrogenations, oxidation reactions (polymerization) and for catalyst research. The unique volumetric dosing system is characterized by high reproducibility and dosing accuracy.

Safe, Flexible and Efficient

The PPR parallel reactor system enables safe, automated and parallel reactions under pressure in 2 to 6 laboratory reactors. Reactors up to 300 ml and 150 bar are available. Hydrogenation and catalyst tests can therefore be carried out quickly and efficiently.

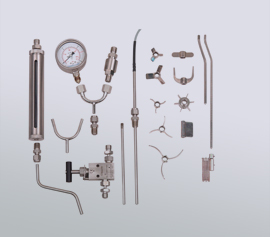

MAGNETIC COUPLINGS & MAGNETIC STIRRER DRIVES

under pressure or vacuum - strong and absolutely tight

Buchi offers a perfected and successful drive concept for different volumes and torque ranges. The pure magnetic coupling without rotating outer parts reliably and safely ensures the power transmission from the motor to the agitator and offers the highest level of safety for the operator. ATEX versions are available.

compact, powerful drives combined with modern control technology

Buchi's magnetic drives combine an electric motor as a drive and the proven Büchi magnetic couplings for power transmission in a single compact unit. The Büchi Cyclone is available in the version up to 75 Ncm and up to 300 Ncm.

MEASURE, CONTROL & AUTOMATION

Data collection and automation - uncomplicated and reliable.

The Buchi measuring and control units offer you direct communication with the pressure reactors. The devices are flexibly configurable and designed for measuring and displaying various process parameters in chemical laboratories and process plants - also in the EX sector. Büchi also offers you the automation of individual processes up to full automation with recipe control.

Play it safe and use EX-protected and appropriately certified reactor technology.

Even in small volumes, in the laboratory or kilolab, explosion protection can play an important role. Because the smallest amounts of liquid educts or products can form a dangerous amount of an explosive mixture as a gas volume.

PLANETARY MIXERS

A flame polished glass connection!

Safe, tight and reliable connections are the crucial point for dependable operations of glass reactors in the chemical and pharmaceutical industry. The Buchi company founders recognized at an early stage that the flexibility of each individual glass joint is of huge importance. The unique buchiflex connection was invented as the basis of a complete modular glass system with interchangeable components.

Combined stirred filter reactor - one device for different reactions and process steps

The filter reactor (10-50 litres / optionally up to 250 litres) is a glass reactor with filtration capability that can be used for stirring, crystallising, homogenising, dissolving solids and separating solids. The glass apparatus with robust PFA-coated cover plate is located in a solid stainless steel frame.

![Buchi MiniPilot [2 …15 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-2-15-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

Stirred glass vessel [2 … 15 liter] with PFA-coated robust steel cover plate

The Reactor's explosion proof design (ATEX) and inert materials allow safe processing of solvents and acids in a completely sealed reaction vessel. The compact standard reactor setup can easily be modified, interchangeable reaction vessels of 2, 5, 10 and 15 liters including interchangeable stirrers are available.

![Buchi MidiPilot [15 … 30 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-30-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

Stirred glass vessel [15 … 30 liter] with PFA-coated robust steel cover plate

The midiPilot is our sturdy multipurpose glass reactor for small volumes. It is specifically designed for applications in kilo lab, for chemical process development and GMP complaint API syntheses. The system is also available as clean-room setup.

![Buchi MiniPilot [2 …15 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruehrapparat-2-15-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)

![Buchi MidiPilot [15 … 30 Liter]](https://www.c3-analysentechnik.eu/wp-content/uploads/2015/12/Glasruerhrapparat-15-30-Liter-mit-Destillationsaufbau-und-Ex-geschuetztem-Motor_S.jpg)